UNC-affiliated startup Triangle Biotechnology’s nanoparticle technology amplifies the power of sound to give scientists rapid, higher-quality sample analysis capabilities—and clinicians hope for pinpointing the right treatments for patients faster and earlier.

The ‘ah-ha’ go-to-market moment didn’t happen for Paul Dayton in his UNC-Chapel Hill lab. It didn’t occur when other scientists on campus expressed interest in using the technology that he co-developed with colleague Samantha Pattenden. Even after publishing findings in an academic journal, he still wondered: Is there commercial appeal?

But one phone call—from a multinational company—immediately transformed his uncertainty into confidence. “When our first paper came out, a large ag-tech company reached out and said, ‘Hey, this technology we just read about sounds awesome. How can we use it in our facility?” recalled Dayton, William R. Kenan Distinguished Professor and Chair of the UNC/NCSU Joint Department of Biomedical Engineering. “That indicated real market traction, because companies were reading our paper and asking for our product.”

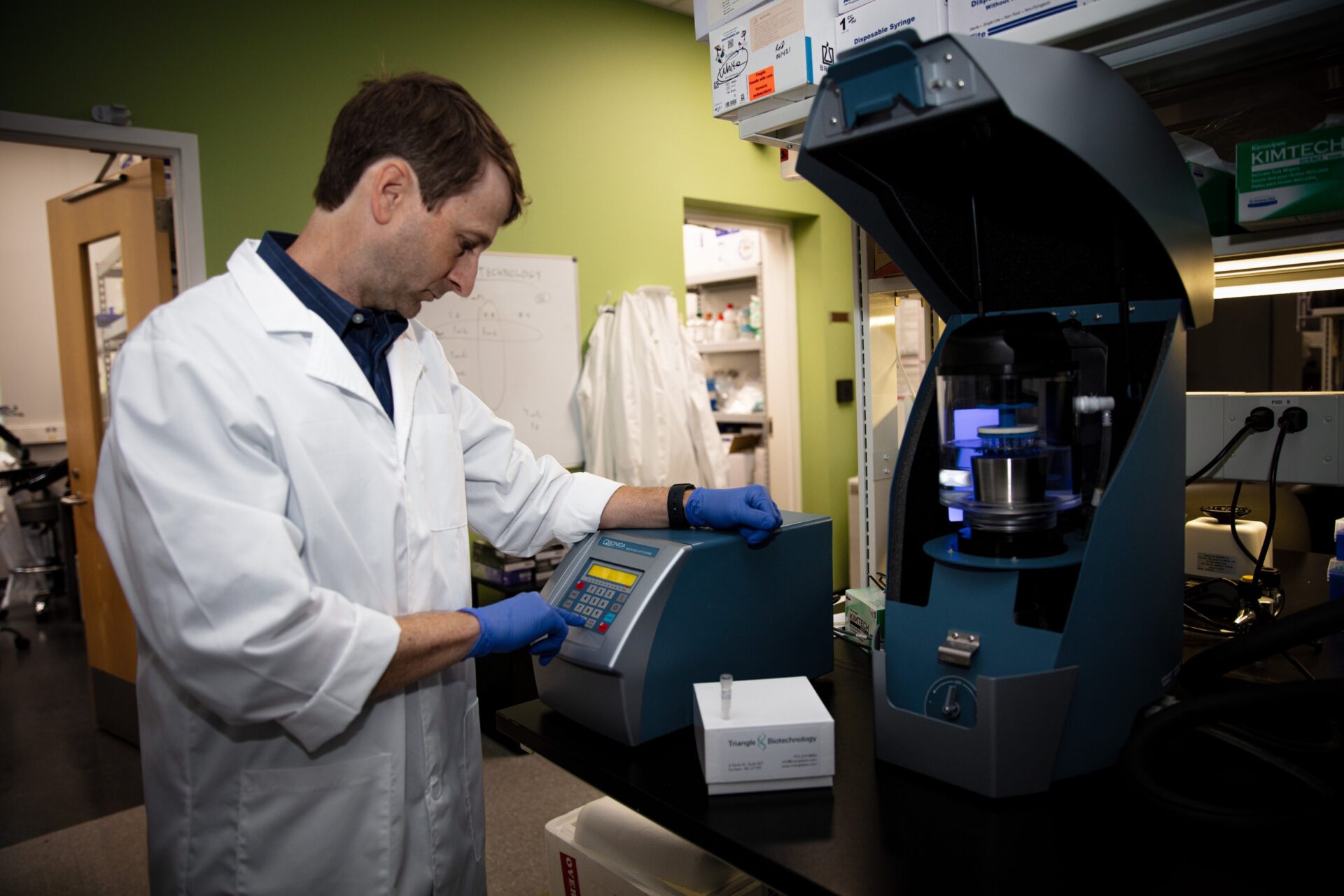

The technology—which Dayton developed with Pattenden, an associate professor of chemical biology and medicinal chemistry at the Eshelman School of Pharmacy—arose from a problem in Pattenden’s lab: extracting chromatin, a mixture of DNA and its associated proteins, from the cell nucleus. It’s a challenging, time-intensive job that scientists traditionally try to solve by placing samples in sonicators, devices that deliver ultrasound to biological samples placed in liquid. The energy creates tiny bubbles that break up tissues and cells, releasing molecules for scientists to analyze. Too often, however, the heat and lengthy time required damage the DNA and other cellular contents, limiting scientists’ ability to analyze them.

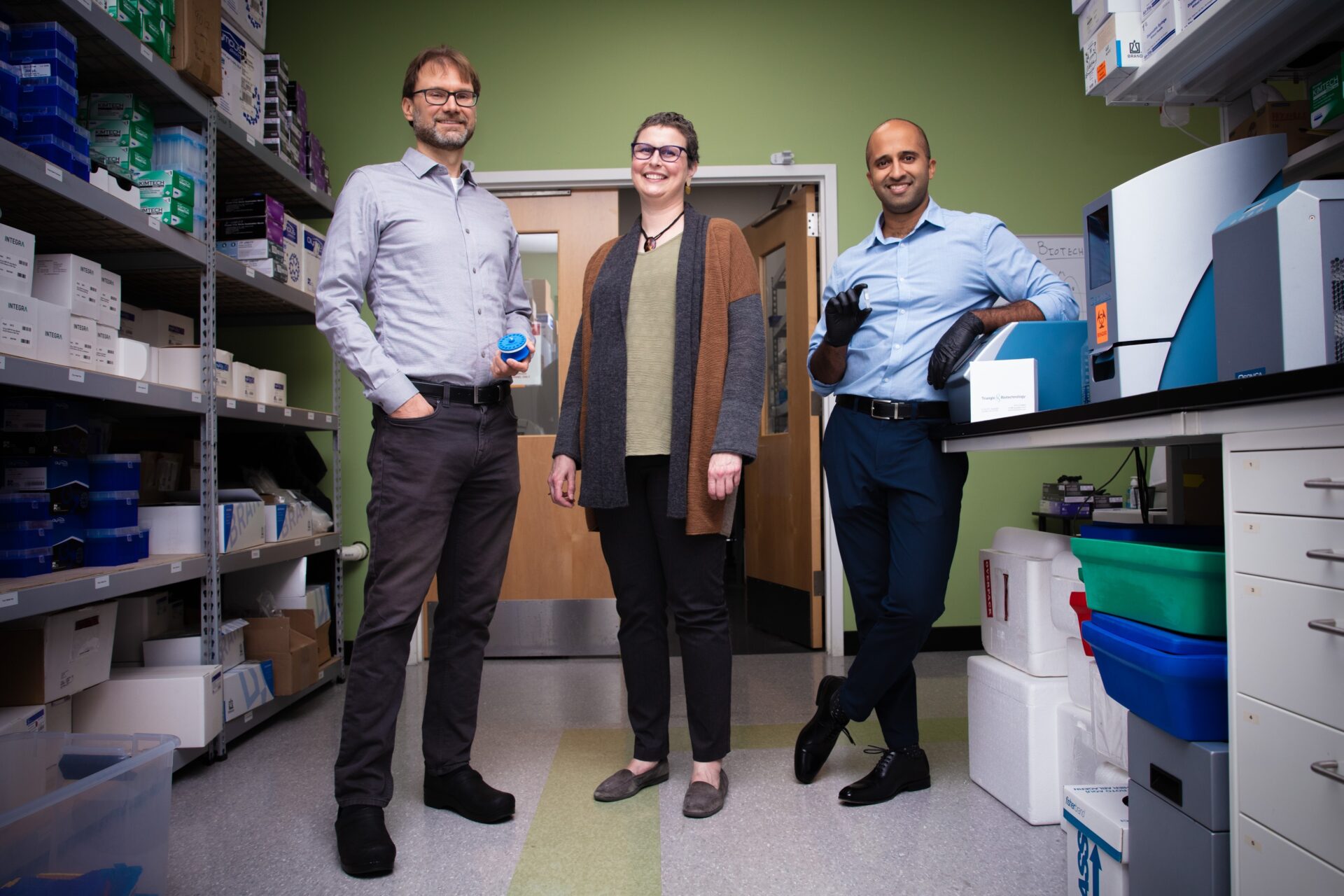

Dayton invented a reagent—a substance that causes a chemical reaction—in the form of nano-sized particles to solve this problem, an issue that vexes many scientists trying to analyze cells or other biological samples. The reagent, which Pattenden says “gets into little cracks and crevices of samples,” became the core technology of Triangle Biotechnology, a startup that Dayton and Pattenden co-founded with biotech executive Joe McMahon. The AAMP technology, named for its ability to amplify sound energy for fast, high-quality sample processing, is already used by several customers and will launch to the market in late 2023.

“Imagine these reagents being nano-sized particles suspended in a liquid solution. When you add the reagent and then sonicate the sample with ultrasound, these particles shake violently like microscopic jackhammers in your sample. They release mechanical energy intensely on a microscopic level and can shear apart macromolecules: cell walls, cell membranes, DNA,” said Sunny Kasoji, CEO of Triangle Biotechnology, who helped develop the reagent technology as a biomedical engineering doctoral student in Dayton’s lab. “If you follow this same process without the reagent, the energy delivery to the sample is much less efficient. By adding the reagent, you get a boost of mechanical energy and more effective extraction of molecules or shearing of DNA.”

The technology does exactly what scientists want. “The reagent breaks up the specimen, but doesn’t destroy it,” Pattenden said. “So, we don’t have a problem with heating or extended sonication times that damage samples.”

The team found that the technology could be used for a variety of samples—and that processing could happen much faster and more efficiently than previously possible.

“We realized if we can do this with cells, we can we do this with other specimens. For example, everyone wants to do high-throughput DNA sequencing inexpensively, but we found that fragmentation of DNA was a massive bottleneck,” said Pattenden. “We saw that if we add our nanodroplets to a sample, we can break up the DNA easily and consistently—the same way every time at the same sonication time. We also proved that we could process 96 samples in parallel, so we’re increasing throughput.”

Triangle Biotechnology is partnering to develop a custom, low-cost sonicator tailored to its nanodroplet technology to bring new high-throughput processing capabilities for many applications to market: DNA shearing for next-generation sequencing, chromatin fragmentation for chromatin-based assays and fixed-tissue processing.

“Processing 96 samples in parallel has been considered the holy grail for over a decade, and no one has been able to accomplish it,” said Kasoji. “There’s nothing like it on the market, so this will be the first of its kind.”

Beyond its initial product launch, Kasoji sees immense potential for Triangle Biotechnology to streamline molecular diagnostics. He believes it can remove a bottleneck at the sample preparation stage when scientists try to lyse (or break up) the cells of microbes like multi-drug resistant, gram-positive bacteria that have “very protective cell walls, like marbles.”

For such diseases—Kasoji points to tuberculosis as an example—better treatment involves rapid diagnosis and identification of the bacterial substrain so that doctors can prescribe the most effective antibiotic. Using traditional culturing methods, identifying the substrain can take weeks to months. In the interim, doctors can only take a scattershot approach, prescribing a concoction of drugs, some of which can counteract with one another. In contrast, molecular diagnostics can provide a rapid turnaround—taking only 24 to 48 hours to identify the substrain—but only if enough DNA can be extracted from the sample bacteria to run the diagnostic.

“The bottleneck with traditional lysis techniques is that you don’t get enough DNA out of samples, so you can’t effectively do molecular diagnostic tests,” said Kasoji. “This is where our technology really helps. We can get enough DNA out of the samples to enable molecular diagnostics and the characterization of TB and the substrain. This way, clinicians can select the appropriate treatment regimen for the patient as early as a few days, without waiting months.”

While traditional techniques extract only 1% of DNA from bacteria samples, Triangle Biotechnology’s product has shown up to a 100-fold increase in DNA extraction. “This allows tuberculosis screening and substrain identification to happen faster and cheaper, making it accessible for low-and-middle income countries,” Kasoji said.

Early funding for Triangle Biotechnology came via personal loans—now repaid—from the three co-founders. KickStart Venture Services also funded a year-long postdoctoral fellowship for Kasoji, covering his salary while he developed the company.

The company then built its next-phase funding strategy around grants. Dayton points to the value of the Technology Enhancement Grant (TEG)—now the Translational Research Grant—from the North Carolina Biotechnology Center that the team worked on with the UNC Office of Technology Commercialization. “That TEG grant allowed us to do funded work as academics to answer commercialization questions,” said Dayton. “We got a lot of preliminary data that supported the commercialization direction and helped the team be more competitive when writing small business grants.”

Those small business grants—namely Small Business Innovate Research (SBIR) grants—were federally funded via the National Institutes of Health and National Cancer Institute. They helped Triangle Biotechnology scientists conduct research and development. In parallel, the company participated in the One North Carolina Small Business Program, which awards matching funds to North Carolina businesses that receive federal SBIR or STTR grants.

“For companies that raise a lot of money right away, there has to be a clear line of sight to a huge profit. For Triangle Biotechnology, that line wasn’t as clear when we first started,” said Dayton. “Our route has been a slower, grassroots build, because we started with small business grants. But the advantage is that the founding team still owns the majority of the company. We’ll probably still raise money, but it won’t have to be as much, and we won’t lose as much equity as if we had gone out to do that right away.”

Currently headquartered in a lab and office space in Research Triangle Park, Triangle Biotechnology worked in several labs and locations across the UNC-Chapel Hill campus, which brought cost and collaborative advantages.

“We started on a single, five-foot bench in [Dayton’s] lab. It was natural that we started there because we had access to the same manufacturing setups that we were using for making nanodroplets, and his lab has a lot of sonicators,” said Kasoji. “Plus, [Pattenden’s] lab was right next door, so we were able to do the same work using the same resources.”

When the company hired another scientist, started ordering its own equipment, and needed more space, it moved into the incubator at the Eshelman Institute for Innovation and then again to the KickStart Accelerator. “We were fortunate that UNC offered us space on campus through the facility use agreement,” said Kasoji. “It was like getting rent for free and was a helpful resource.”

As the company grew to its current five-person scientific team and two-person business staff, its talent needs evolved. Pattenden, who initially served as Triangle Biotechnology’ day-to-day expert on molecular biology, had to attend to her full-time academic responsibilities. So, when Kasoji graduated and joined as CEO, the company hired a full-time scientist. “As we expanded and got more grants, we needed more scientists on board to start increasing productivity,” he said.

Dayton and Pattenden feel that the company was wise to bring on a business person with prior biotech venture success—McMahon as the company’s first CEO and current board member—to help the team navigate the business landscape. In addition to his executive role, McMahon has provided keen advice on identifying effective board members. “Working with Joe, we selected people who would work for equity and had experience expanding small ventures in North Carolina and across the U.S.,” said Pattenden. “What business decisions need to be made? How do you get a product to market? They bring different levels of scientific and business advice for moving the business forward.”

Pattenden and Kasoji, both with extensive academic expertise but no prior entrepreneurial experience, say building a startup and protecting its intellectual property (IP) was a learning endeavor. “It shifted my perspective on innovation in the lab and how we might protect intellectual property or control how it’s applied,” said Pattenden, who now educates others about IP protection. “A lot of people in my field aren’t aware of how to do this kind of thing, so now I talk to colleagues about patents a lot: ‘What can we do with this technology? Maybe we can patent it. Or is there a way to license it?’”

The team gained insights on protecting IP and building the company when working with University resources like Innovate Carolina’s Office of Technology Commercialization, whose commercialization experts provided guidance on the IP pathway and talked to potential partners on the company’s behalf. Triangle Biotechnology also turned to KickStart Venture Services for coaching and connections and to the Patent Landscaping and Market Research team to assess competition and the wider market.

Over time, Kasoji saw his entrepreneurial and executive learning shift. “It started off big picture: Who is the customer? What is the market? Does our technology actually solve an issue?” he said. “Today, a lot of my entrepreneurial research is self-development, like accounting and finances. Now that I’m taking on the CEO role, I need to speak that language.”

Beyond the University, Triangle Biotechnology has received advice from the Small Business and Technology Development Center (SBTDC), which also provided two graduate student interns to conduct customer discovery and market research. The growing set of resources for startups is one reason Pattenden encourages students and faculty with ideas or inventions to take the entrepreneurial plunge. “There are a lot of resources available to help translate your technology—whether licensing it or starting a company,” said Pattenden. “I’ve seen resources grow exponentially at UNC since we started in 2017, so it’s possible to do this even when you have no experience doing it.”