Ask founder and CEO Dan Estay to talk about startup SonoVascular, and he’ll rattle off all the impressive insights you might expect from an executive with his decades of med-tech experience: the intricacies of science and technology, clinical studies, business strategies and funding trajectories, to name a few. But he’ll also mention something less expected: hockey. “When the famous hockey player Wayne Gretzsky talked about what makes a hockey player great versus just good, he’d talk about skating to where the puck is going to be, not where it has been,” said Estay, paraphrasing the hockey great’s famous quip. “I think that’s a good metaphor for us at SonoVascular.”

The parallel that Estay draws between athletic anticipation and SonoVascular’s business strategy encapsulates the company’s place in a dynamic medical device market that is shifting to improve outcomes for patients with blood clots. In the past, physicians leaned almost exclusively on drugs to dissolve blood clots, including oral anti-coagulants and thrombolytics (clot-busting drugs) to treat people suffering from deep-vein thrombosis (DVT)—a condition that occurs when clots form deep within the veins of the body (often the legs)—or pulmonary embolism (PE)—a life-threatening emergency that occurs when clots migrate from veins and become lodged in the pulmonary arteries of the lungs and block blood flow. While good at dissolving certain types of clots, high doses of thrombolytics carry significant risks: increased risk of internal bleeding and intracranial hemorrhages. Patients receiving intravenous infusions of the drugs must be monitored in hospital intensive care units (ICUs) for many hours. The magnitude of the problem is huge, with DVT and PE affecting approximately 900,000 people and costing $10 billion in the U.S. each year.

Given these risks and costs, vascular surgeons and interventional radiologists and cardiologists have increasingly turned to using mechanical devices to capture and/or suction out clots, without the use of drugs. However, Estay notes that emerging data on mechanical-only therapies point to additional concerns. “Devices that rely solely on mechanical mechanisms tend to be larger, more aggressive devices, so there are some safety concerns around those,” said Estay. “Data now coming out shows that devices that don’t use any thrombolytic drug, in certain settings, are less effective on some important clinical endpoints.” With patients and physicians facing real concerns about all-or-nothing drug versus mechanical treatments, Estay believes a more balanced approach is called for.

“We’re combining pharmacological and mechanical approaches into one hybrid system to get a more effective and safer outcome that does not require the patient to be treated in the ICU. The most novel aspect is that we use intravascular ultrasound in combination with microbubbles and low-dosage thrombolytic drugs.”

Dan Estay, CEO of SonoVascular

“Historically, patients were treated purely with drugs, and then we saw the pendulum swing to purely mechanical therapies,” said Estay. “We suggest that the pendulum is going to swing back toward the middle because physicians would like to have the benefit of both approaches.” That middle ground—a combined pharmaco-mechanical approach—is where the SonoVascular team sets its sites, anticipating where the market is moving, much like an athlete intuitively positioning themselves for the next play.

SonoVascular’s SonoThrombectomy™ system is a novel intravascular catheter that brings together several elements: ultrasound, microbubbles, low-dose thrombolytic drugs and a less aggressive mechanical retrieval/aspiration device. “We’re combining pharmacological and mechanical approaches into one hybrid system to get a more effective and safer outcome that does not require the patient to be treated in the ICU,” said Estay. “The most novel aspect is that we use intravascular ultrasound in combination with microbubbles and low-dosage thrombolytic drugs. And based on what we’ve seen, we believe that after a physician performs that first part of the procedure, they are then better able to use a gentler mechanical device to physically extract any residual clot that remains, which improves your safety profile.”

900,000

people in the U.S. affected annually by blood clots

$10B

in U.S. health care costs related to blood clots

$6.1M

in funding raised to date by SonoVascular for novel SonoThrombectomy™ procedure

Because SonoVascular’s approach significantly reduces the level of thrombolytic drugs to optimize effectiveness and safety and can be performed to remove all types of blood clots within the catheterization laboratory (cathlab)—with no ICU stay required—it offers a combination of benefits previously unavailable to patients and physicians.

Academic collaboration, commercial innovation

The ultrasound catheter behind SonoVascular’s unique procedure works in tandem with microbubbles and thrombolytic drugs to better break up clots. Xiaoning Jiang, PhD, Dean F. Duncan Distinguished Professor in the NC State University Department of Mechanical and Aerospace Engineering, and Paul Dayton, PhD, William R. Kenan Distinguished Professor and Chair of the UNC-NC State Joint Department of Biomedical Engineering (BME), developed the underlying ultrasound technology. Research collaborators for nearly 15 years, Jiang and Dayton published a research paper in 2017 at the conclusion of a National Institutes of Health R01 grant they secured from the National Institutes of Health to investigate intervascular coronary imaging. A description of their research published in a vascular journal caught the eye of Estay, who contacted Jiang to express interest.

“The great collaboration between Xiaoning’s lab at NC State—which has world-class expertise in pure engineering and transducer design—and our lab at UNC-Chapel Hill which focused on a lot of applications—the chemistry, microbubbles and testing—in combination with the clinical expertise of UNC physicians allowed this project to be very successful.”

Paul Dayton, PhD, William R. Kenan Distinguished Professor and Chair of the UNC-NC State Joint Department of Biomedical Engineering

“Amazingly, the second or third day after the publication, Dan sent me an email saying that he was located in the Research Triangle area and was a veteran in the field with years of experience,” said Jiang, who along with Dayton, serves as a scientific advisor to SonoVascular. “We met and I showed him around our lab at NC State. He showed interest, and the company started in 2018 right after the paper published.”

By combining the respective research strengths of both universities, Jiang’s and Dayton’s labs built a productive partnership. “The great collaboration between Xiaoning’s lab at NC State—which has world-class expertise in pure engineering and transducer design—and our lab at UNC-Chapel Hill which focused on a lot of applications—the chemistry, microbubbles and testing—in combination with the clinical expertise of UNC physicians allowed this project to be very successful,” said Dayton. “We’ve had students go back and forth between our labs who bring devices to Carolina or microbubbles to NC State so we can all do studies together.”

The university’s tech transfer arms—the NC State Office of Research Commercialization and UNC Office of Technology Commercialization—work together to manage intellectual property assets that are licensed to SonoVascular, some of which are jointly owned by the schools. “We have an intellectual property sharing memorandum across the campuses, so some of the patents are filed through NC State, and some are filed through Carolina,” said Dayton. “The two universities have a path forward for negotiation, so it’s worked very smoothly and has been very enabling for the commercial direction.”

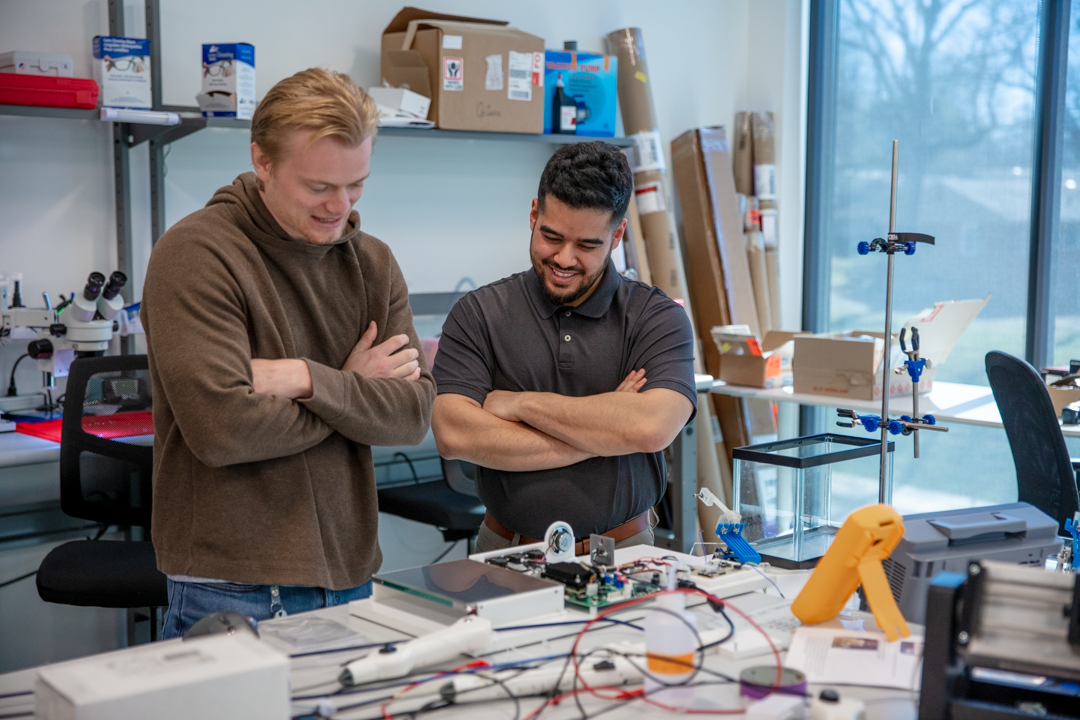

John Ranshaw, senior engineer, and Mohamed Lahlou, principal engineer, at work with SonoVascular’s catheter device inside the company’s laboratory in Chapel Hill, NC.

‘Very impressive’ studies

SonoVascular has already conducted in-vitro bench studies and animal studies, and its first human studies are scheduled for 2024. The bench and animal studies dealt with important questions and created a proving ground. “When dealing with clots, you have to consider questions: What type of clot are you treating? Is it a fresh, acute clot that is easier to treat? Or is it an older, more organized and chronic clot that is more difficult to treat?” said Estay, who noted that the bench study focused on difficult-to-treat chronic clots. “Based on what we saw in our bench study, the device was very effective in breaking down chronic clots in a safe manner.”

John Ranshaw, a senior engineer for mechanical systems at SonoVascular, said the bench study was designed to closely replicate how physicians work in the clinic. “We worked to mimic the human body externally, including the clot, and took the study to the next level to answer the question: How would a clinician use the device to treat patients?” said Ranshaw. “Physicians are the masters of their craft. What was nice about being connected to the university is that we got UNC clinician feedback on how they would like to use the catheter, their techniques and how they would articulate or rotate it to get the best outcome. We had good success on the bench, and it also translated well to the animal study for the acute clot model.”

The studies also answered questions about efficiency. “One of the key questions from clinicians was how long the procedure would take, because if it complicates their workflow and takes too much time, that would be a negative,” said Estay. “However, when you extrapolate the data, our bench study showed that someone can perform our procedure in a reasonable amount of time—and that it fits into the current workflow of standard interventional procedures.”

Beyond the bench, Estay said the company “completed a very successful series of animal testing with the DVT system.” The lead operator of the animal study was Dr. William Marston, a vascular surgeon at UNC Health and professor at the UNC School of Medicine. “Dr. Marston treats DVT patients every day, so for him to be the one operating the catheter and seeing how it works and being excited about it was very important,” said Estay. “You’re seeing the results angiographically. You’re seeing what the vessel looked like before you created the clot. Then, you look at the vessel pre and post treatment, and the results were very impressive.” Next up are human clinical studies in Latin America during 2024, followed by studies in New Zealand and the U.S. The human studies are the next step toward securing Food and Drug Administration (FDA) approval.

Path to impact: Lessons from SonoVascular’s entrepreneurial journey

Funding Approach

Beyond federal grant dollars secured by Jiang’s and Dayton’s labs to research the foundational technologies, the earliest funds for SonoVascular came from two primary sources: Estay’s personal investment and the KickStart Venture Services program at UNC-Chapel Hill. “We secured a $40,000 grant from KickStart Venture Services that allowed us to do more testing with the NC State team as well as build the first prototypes in the catheter format,” said Estay. “We got a lot of mileage out of those prototypes and ultimately used them in an animal study. We used those prototypes many times, and they lasted far longer than we thought they would.”

With the animal study completed in 2021, investors took notice. “After the animal study, investors started saying, ‘We like what we see,’ and at that point, we raised about $2.2 million dollars,” said Estay, who feels support from university venture investment programs proved vital. “The lead investor was UNC’s Carolina Research Ventures (CRV), and we also had a few investors from the Wolfpack Investor Network (WIN) at NC State. We were able to contact numerous people in the university network to help raise that initial investment.”

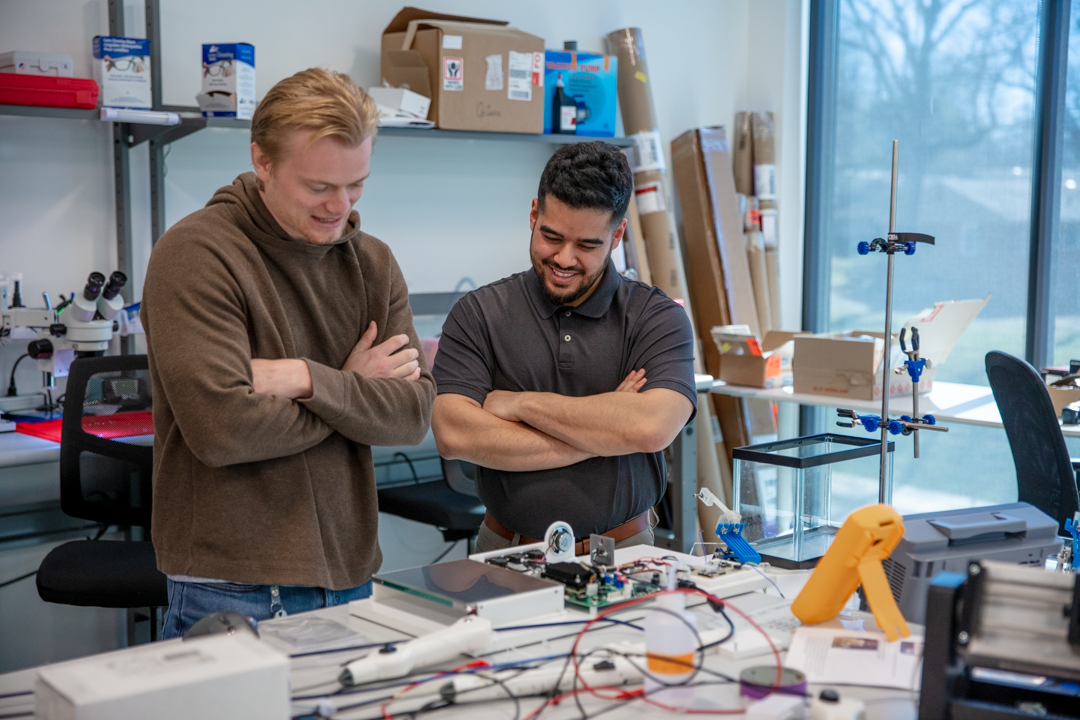

The SonoVascular team in its company headquarters located in Chapel Hill, NC, which includes office and lab space for its growing engineering team.

In 2023, SonoVascular raised an additional $3.3 million, a second tranche of funding that included follow-on investments from CRV and WIN and an initial investment from venture capital firms Harbright Ventures of Cary, North Carolina and ShangBay Capital of Palo Alto, California. The company also secured investment dollars from the North Carolina Biotechnology Center as well as a venture loan from Silicon Valley Bank. All capital raised to date, which now exceeds $6 million has been convertible note funding, said Estay, who indicated the company is now working on a Series A equity round. “We want to raise at least a $10 million Series A, which would allow us to complete our first human studies and meaningfully advance product development,” he said. “The human study is the biggest inflection point we’ll have as a company and, with good data, we’ll then be in position to raise in excess of $20 million, which will propel the company into the future.”

Company location

After research activity moved off campus from Jiang’s and Dayton’s labs, the company began working virtually and then subleased lab and workstation space in Raleigh near the NC State campus. Estay said it is valuable to remain located close to the universities, which provide access to faculty founders and world-renown clinicians. In 2023, SonoVascular moved to its current location in Chapel Hill, which includes nearly 2,800 square-feet of space, to support a growing engineering team and need for additional lab space as the company was scaling up product development and system testing capabilities.

People and talent

When he licensed the technology from the universities and launched the company in 2018, Estay was SonoVascular’s original employee. After the company raised its first $2.2 million in capital, it began hiring staff in 2022, including its first engineers to accelerate product development and pre-clinical studies. SonoVascular has grown to employ eight current employees, six of whom are engineers. Its talent strategy is to focus early talent resources on product development. “Engineering is where you want to dedicate most of your resources, so I relied heavily on the university network in RTP to find and build a team of the right people to translate the technology into a commercial product,” said Estay, who noted that med-tech expertise, which has traditionally been more available in other med-tech hubs around the U.S., is now on the rise in North Carolina. “With the joint biomedical engineering program at UNC and NC State and the biomedical engineering program at Duke, we’re seeing a growing talent pool specific to the med-tech market that didn’t exist before in the Research Triangle region.”

Ranshaw is a prime example of emerging med-tech talent in the region. After completing his bachelor’s degree at UNC-Charlotte, he enrolled in the UNC-NC State Joint BME MedTech master’s program, graduated in 2022 and immediately joined SonoVascular. His work at SonoVascular is a natural extension of his master’s experience. “The BME MedTech master’s program gave me an industry overview of med-tech from start to finish that I use at SonoVascular. I learned how to find the need, develop prototypes and complete all the documentation involved with the commercialization lifecycle,” Ranshaw said.

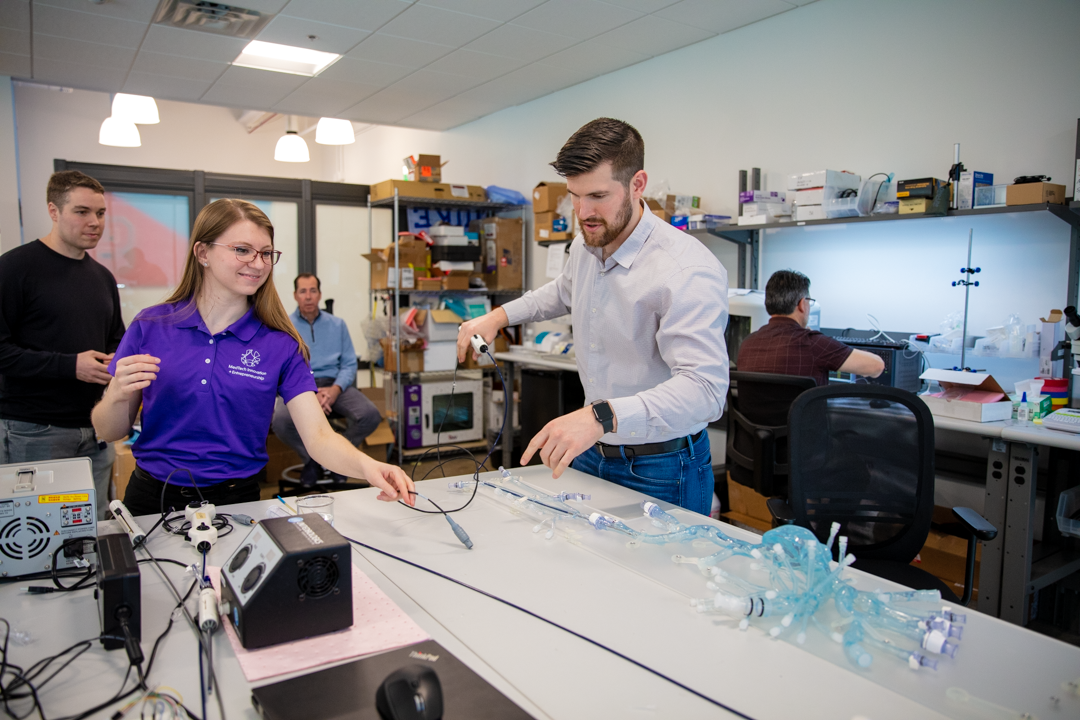

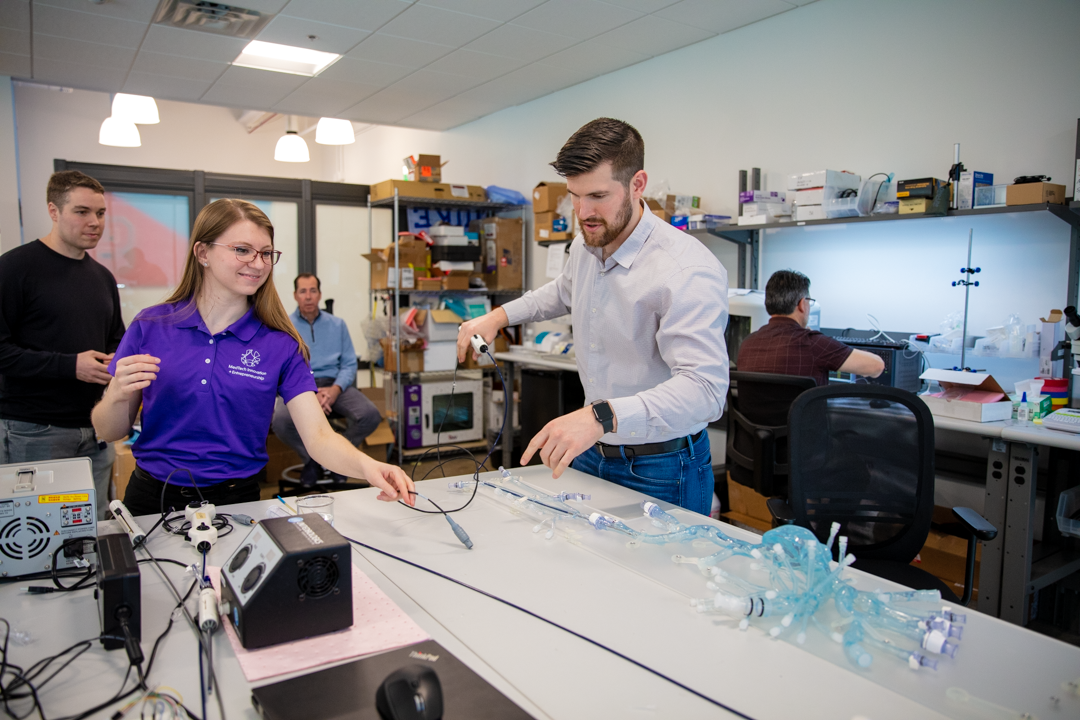

Hannah Florez, SonoVascular engineering intern and student in the UNC-NC State Joint BME MedTech master’s program, and Jacob Ruprech, director of engineer, work with the intravascular catheter.

As the engineering programs at RTP-area universities prepare students to support the region’s growing med-tech market, companies like SonoVascular provide opportunities for graduates to immediately put their engineering expertise into practice following their studies—or return to the Triangle area after pursuing graduate education or professional roles elsewhere. For example, Jacob Ruprecht, SonoVascular’s director of engineering, earned a bachelor’s degree in biomedical engineering from Duke University before earning a master’s degree at the University of California, Berkley. After gaining several years of R&D engineering experience working at California-based medical device companies, Ruprecht returned to the RTP area to lead engineering efforts at SonoVascular, just down the road from his undergraduate alma mater in Durham.

For Craig Nichols, SonoVascular’s director of technical operations who earned a bachelor’s degree in biomedical engineering from the UNC-NC State Joint BME program a decade ago, the program’s emphasis on problem solving still rings true. “What translated most directly from my undergrad experience in Chapel Hill to my professional work is the emphasis on figuring things out. As a biomedical engineer, you don’t have a strict focus on one engineering discipline—you’re exposed to everything,” he said. “In school, we were constantly put in new situations, and there was a lot of emphasis on students taking initiative to figure things out. You develop a comfort with approaching subject matter you don’t understand, asking experts the right questions and dissecting problems.”

Hannah Florez, an engineering intern at SonoVascular and current master’s student in the UNC-NC State Joint BME MedTech program, appreciates the program’s emphasis on commercialization. “There is a big focus on startups and how to be a well-rounded engineer who understands every step of the process,” she said. “The MedTech master’s program has an intentional focus on entrepreneurship, lets you dig in to the technology and helps you get a hold on how to start a company. Working at SonoVascular as a BME student, I find there are things I learn in class that I use at work the next day.”

Entrepreneurial education

Despite extensive executive and med-tech industry experience, Estay said making the transition to startup CEO comes with a steep learning curve. “What’s been interesting about the journey is that you leverage everything you’ve learned over the years, but you’re also learning a ton in the process,” he said. “You have to be a quick study because, based on what I know now, there are a few things I did not fully appreciate when the company was founded in 2018”. He further noted, “One that comes to mind is that I probably underestimated the amount of time and work required to translate technology that was invented within the university setting into a commercially viable product.”

Mentorship has proven critical. Estay has “tapped into people who have startup expertise and have done this before,” including people like SonoVascular board chair Bill Starling, a serial entrepreneur, CEO, VC, angel investor, and member of the UNC-NC State BME Industry Advisory Board. “Bill has done this many times successfully, so he is someone I talk to—at least weekly—to pick his brain and get his advice,” Estay said.

Estay has also observed that the Research Triangle region has an unusually close-knit, interconnected med-tech community of researchers, entrepreneurs and funders—and he encourages other startup leaders to leverage this network to make connections, learn and access resources. “Everyone has a shared interest of trying to create a bigger med-tech community, so people are predisposed to help one another,” said Estay. “To get early-stage companies off the ground, you have to rely on the local ecosystem to bring it all together—from the technology and initial capital to talent and other resources. SonoVascular has been successful at leveraging resources in the local ecosystem, through the universities and investors, to get to where we are today.”

Want to learn about UNC-affiliated startups that turn research and ideas into impact?

Check out more stories from Innovate Carolina’s Idea-to-Impact series. You’ll discover insights from inventors and entrepreneurs who are leading startup companies and innovative ventures that create human and economic impact in North Carolina and beyond.

| UNC-CH

| UNC-CH