Cell Microsystems, a company with UNC-Chapel Hill origins, is leapfrogging traditional technologies for single-cell cloning, culturing, analysis and isolation. How does the firm help scientists in pharma-biotech organizations speed therapeutic breakthroughs by culturing 10 times more cells in one-tenth of the time?

Gary Pace, PhD, remembers precisely when he realized that Cell Microsystems had to change. It was 2014, and Pace had recently signed on as CEO of the UNC-Chapel Hill spinout company. He sat in a meeting listening to feedback from potential customers. “We had convened a group of academic scientists talking about what they need. Have they tried our product? Where can we take it?” he recalled. “It was at that meeting that I realized that we couldn’t take a technology perspective on the product. We had to take a customer perspective, and that’s when we flipped it around. We started identifying unmet customer needs.”

Cell Microsystems’ technologies allow researchers to image, identify and isolate viable single cells and clonal colonies for downstream analysis. Its core CellRaft technology was invented in the lab of former Carolina biomedical engineering professor Nancy Allbritton, MD, PhD, who co-founded the company with chemistry professor Christopher Sims, MD, and researcher Yuli Wang, PhD, in 2010.

“It struck me at the time that the technology had a lot of advantages, but that the company’s focus had to be on product applications. There had to be a reason why somebody would buy it,” Pace said. “In a commercial sense, it was a technology in search of a reason. The Allbritton lab had published a lot of papers on it, and done a lot of characterization and unique experimentation. But what gets published in an academic journal is not necessarily a commercially viable product, so it was the company’s job to find where the technology belonged.”

Fast forward through 10 years of testing its technology on a wide variety of cell lines and continually developing the product based on customer needs. Pace’s intuition to shift to a more market-centric perspective has paid off. Today, Cell Microsystems has a decade-long record of success and growth, helping researchers in pharma-biotech and academic industries with a variety of practical applications: CRISPR gene editing, stem cell research, immunology, organoid studies and genomics. Customers include Pfizer, Duke University, Genentech, Kite (a Gilead company), Memorial Sloan Kettering Cancer Center, UNC-Chapel Hill and the Albert Einstein College of Medicine, among others. A common thread? Scientists working in these fields and organizations need to investigate single cells to understand and develop treatments for diseases that manifest in the body’s cells and tissues.

An early breakthrough for the company came by way of CRISPR, a powerful technology that allows scientists to precisely modify genes. CRISPR works like molecular scissors, cutting DNA at specific locations and helping scientists add, remove or replace genetic material to treat genetic diseases. “Landing on CRISPR gene editing as our first single-cell workflow application was pivotal. We played with other applications before that, but they didn’t address a particular market,” said Pace. “Once we recognized CRISPR as a key application, we saw there was a whole world out there built around clonal propagation from single cells—a world that has only gotten bigger. CRISPR allowed us to begin to focus on specific markets.”

Traditionally, scientists in the world of single-cell biology have relied on several methods—single-cell RNA sequencing, limiting dilution and fluorescence-activated cell sorting (FACS)—to clone individual cells for analysis. However, the traditional approaches have major drawbacks: destruction of the original cell, labor- and time-intensive processes, low yield rates and the propensity of cells to not thrive and divide when segregated. Plus, they can fall short of allowing scientists to document monoclonality—proof that a cell line originated from a single cell—a regulatory requirement they must meet when working with therapeutic cell lines.

“We took a completely different approach, which is our proprietary CellRaft Array that allows cells to settle into individual micro wells but stay in fluid communication with all the other cells on the array.” said Pace. “The cell is segregated but shares media with other cells. That has substantially increased the viability and the yield of single-cell clones and has also allowed us to develop and validate applications for over 100 different cell lines.”

The CellRaft Array technology allows scientists to get better results, faster. “The traditional way of doing single-cell clonal propagation is a 10-week process, but with our CellRaft Array, you can go from single cells to a plate full of clones in five to 10 days,” said Pace. “From an efficiency perspective, we can do in 10 days what takes 10 weeks using traditional manual methods. And you get a 10-fold yield increase. Our technology creates 10 times the yield of viable monoclonal colonies in only one-tenth of the time.”

Pace also points to a reduction in materials. When a lab uses the traditional limiting dilution method, for instance, scientists must manipulate the plates at least every week, a process that requires reagents and plastic materials. The Cell Microsystems solution eliminates these steps. “Not only do we save time, but we significantly reduce the use of reagents and plasticware as part of the process,” he said.

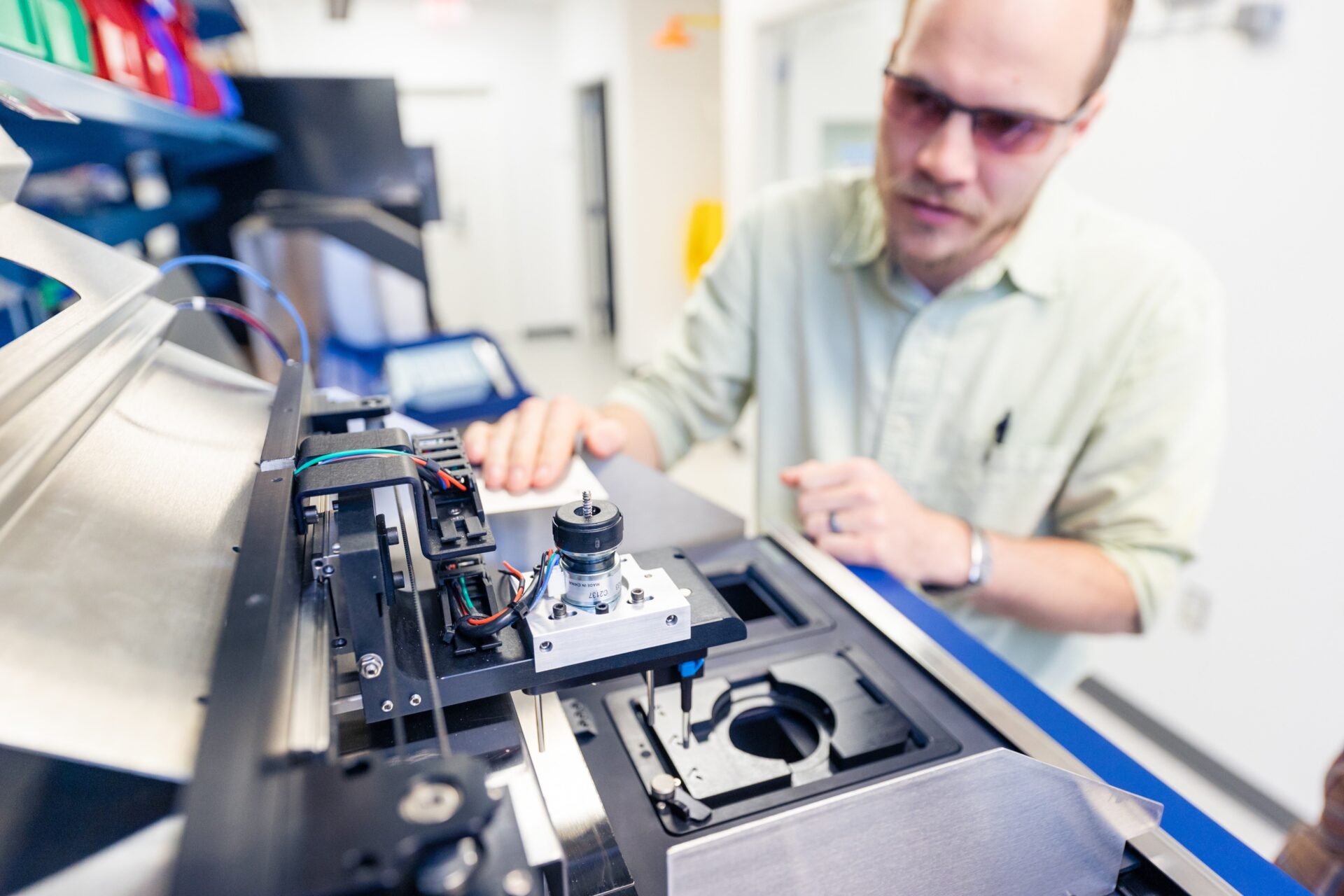

To extend the power of its core technology, the company developed an automated platform that incorporates brightfield microscopy and fluorescence imaging that can be performed over time. With an embedded inverted microscope, the platform allows scientists to watch a single cell divide—from two cells to four, and from four cells to eight, and so on. Images captured along the way then help researchers identify specific cell attributes (phenotyping) that are important for further analysis.

The platform is driven by Cell Microsystems’ proprietary software called CellRaft Cytometry, which automates how the system isolates cells and captures images. The software’s image-based verification capabilities let researchers meet regulatory requirements for proving monoclonality. Researchers can also specify precise attributes they’re interested in—such as cell shape, colony size or fluorescence intensity—and then identify cell colonies that meet their specifications. The software brings together insights on single-cell propagation, clone colony size and phenotypic analysis. “Our CellRaft Cytometry software creates a Venn diagram of those three distinct observations, and then you can isolate just the cells in the position on the array that overlap all three of those circles of the Venn diagram,” said Pace. “We’ve collapsed a number of the different modalities of a single-cell workflow into a single platform. And that’s very powerful. No one else has that.”

Cell Microsystems licenses intellectual property for the foundational technology invented at UNC-Chapel Hill used in the CellRaft product, and it has worked with the UNC Office of Technology Commercialization over the years on other joint patents for the company’s automated platform. The company has also filed a variety of patents on its own inventions. “Our primary approach to intellectual property protection is patents. We have a pretty substantial patent estate, not only what we license from UNC-Chapel Hill, but other inventions that we have filed as a company itself,” said Pace. “We’ve continued to generate additional divisionals and continuations as we’ve mined the original specification for permutations. So, we cover not only what we sell today, but also have a picket fence strategy to protect us from competition in terms of other possible avenues.”

With a well-integrated set of technologies built around user needs, researchers find a lot of punch packed into a single solution. “For scientists, there are benefits across the board: high viability, very efficient, amenable to a large number of cell lines and an integrated platform that gives you cytometric data that you can’t get anywhere else,” said Pace.

As a UNC-Chapel Hill spinout, Cell Microsystems’s funding approach evolved as it graduated from an on-campus startup to a commercial standout. While still at the University, it received a commercialization grant awarded by KickStart Venture Services—a venture-focused team that is part of Innovate Carolina, the university-wide initiative for innovation, entrepreneurship and economic development. KickStart also provided fellowship funding, which paid for one of the company’s early employees.

To jumpstart research and development, the company began submitting applications for federal Small Business Innovation and Small Business Technology Transfer (SBIR/STTR) grants. Given the extended SBIR/STTR grant cycle—funding notices can take 9 to 12 months to arrive—the company submitted one or two grant applications each cycle. The strategy was to keep the pipeline of potential grant funding full. “Obtaining our first SBIR Phase 2 grant was pivotal because that allowed us to hire a couple of engineers and build our first automated platform system,” said Pace. “The National Institutes of Health (NIH) SBIR/STTR program has been very important to the company’s development. Over the years, we have received over $15 million in NIH SBIR funding.”

Pace said Cell Microsystems received economic development support from NC IDEA and the North Carolina Biotechnology Center’s loan programs. It also secured grant-matching dollars from the North Carolina Department of Commerce’s NC One Program, which awards matching funds to North Carolina businesses that receive federal SBIR or STTR awards.

“Raising so much NIH funding was a very attractive approach to complete the development of commercially viable products. But we couldn’t really build a commercial organization with SBIR/STTR funds because those dollars are restricted to research and development. You can’t use them for patent costs and commercial activity,” explained Pace. “The only way we’re really going to scale the company and bring in commercial expertise was to raise investment.”

In 2019, Cell Microsystems initially raised $1.85 million in convertible notes funding, followed by a subsequent $12.6 million Series A equity financing round in 2021. Telegraph Hill Partners, the lead investor in the 2021 round, invested an additional $6.5 million as part of Cell Microsystems $13 million Series B financing in 2023. “Telegraph Hill Partners’ investment in us as a partner—not just as an arm’s length investor—has made all the difference in the growth of the company. The foundation that we’ve built can now be commercialized at scale. We’ve transitioned from the development phase to the commercial phase.”

Initially setting up shop in laboratory space at UNC-Chapel Hill, Cell Microsystems soon found that it needed to migrate off campus. “We moved the company from the UNC campus and laboratory of Nancy Allbritton to the First Flight Venture Center, and that got us out of the university environment where we were founded,” said Pace. “The First Flight Venture Center allowed us to start focusing on the commercial steps we should take, which was important.”

The need for physical space grew as the number of employees ticked up. “When we first moved to First Flight Venture Center, there were four of us sitting in one office with all the desks pushed together, trying to get something done and still relying on the university lab facility to run some experiments,” said Pace. “As we grew, we added an optical engineer, a mechanical engineer, a software engineer and some cell biology expertise. Over time, we wound up occupying three labs plus six offices at First Flight.”

When Cell Microsystems outgrew space capacity at First Flight Venture Center, it began looking for a new headquarters. It found its new home at the Alexandria campus in Durham, now occupying 15,000 square-feet of office and lab space. But finding a location that met all of its needs wasn’t an effortless slam dunk. “The challenge was that we needed space for cell and molecular biology. We needed space for polymer manufacturing. We needed space for instrument design and engineering and testing. And we needed a place where software engineers could sit alongside these other functions,” said Pace. “Only the Alexandria campus met all those criteria.”

Pace recalls that there were only four people—plus the faculty founders—who worked on Cell Microsystems’ first SBIR Phase 2 grant submission. Since that time, company staffing has increased to more than 40 employees. The company’s talent strategy has evolved, too. “In terms of personnel and skill sets, we built them over time as we transitioned from a development-focused to a commercial-stage company,” Pace said. “As a development-stage company, you focus on scientists and engineers, and as a commercial-stage company, you bring in sales and marketing expertise.”

With an abundance of life science talent in the Research Triangle Park region, Cell Microsystems has successfully recruited many employes itself—via word-of-mouth or local connections. “We recruited from the local universities and posted job openings on the NC Biotech site,” said Pace, who said the company had to “kick it up a notch” as it started recruiting commercial candidates focused on sales, marketing, finance and other functions. “Telegraph Hill Partners has been a good source of networking into commercial expertise, and now we use recruiters a lot to find a higher level of experience.”

A self-described “scientist by training and lawyer by mid-life crisis,” Pace said that much of his entrepreneurial education has come through on-the-job-training. He’s chiseled a keen understanding of the industry through years of running operationally oriented life science practices within large and small companies. His scientific training has served him well when running point as Cell Microsystems CEO. “Coming from a scientific and technology background, once I could articulate a framework on where to take the company, it was easy to see how to get there and which steps to take,” he said. “Executing that plan was the challenge.”

For Pace, top entrepreneurial leadership lessons have centered around talent. “The thing I’ve had to learn most about are HR issues: motivating teams, keeping people together, keeping people going in the same direction, keeping people from looking for other jobs,” said Pace. “For example, you can’t make a counter offer when people tell you they’re leaving. You have to stop them from thinking about leaving in the first place. You have to have the right culture, the right environment and the right HR programs in order to keep people dedicated.”

Ten years into his journey with the company, Pace sees a wide and bright horizon dotted with opportunities: expanding technology applications and markets, the development of new instrumentation and the integration of instrument platforms from other companies, such as those from Fluxion Biosciences, which Cell Microsystems acquired in 2023. Still, when it comes to pinpointing exactly what’s allowed his company to thrive while others wilted, Pace is contemplative, perhaps thinking back to the early customer meeting when he realized the imminent need to change the company’s strategy.

“I sometimes think back about why we’re still here and growing, and other companies of our vintage and origin aren’t. I believe one big reason we’re still around is because of perseverance and adaptation,” he said. “A lot of startups just have one thing that they try to pursue at the early stage, but they don’t really know how to make adjustments and evolve unless they bring in proper management. But Cell Microsystems has adapted and persevered through all kinds of challenges over the years. Talent is important. Financing is important. Environment is important. Customers are important. Satisfying unmet needs is important. We could list a hundred things. You have to adapt to make them all come together.”

Want to learn about UNC-affiliated startups that turn research and ideas into impact?

Check out more stories from Innovate Carolina’s Idea-to-Impact series. You’ll discover insights from inventors and entrepreneurs who are leading startup companies and innovative ventures that create human and economic impact in North Carolina and beyond.